Gabriel Kohlmaier

Hauptdesigner

Management und Hardwaredesign

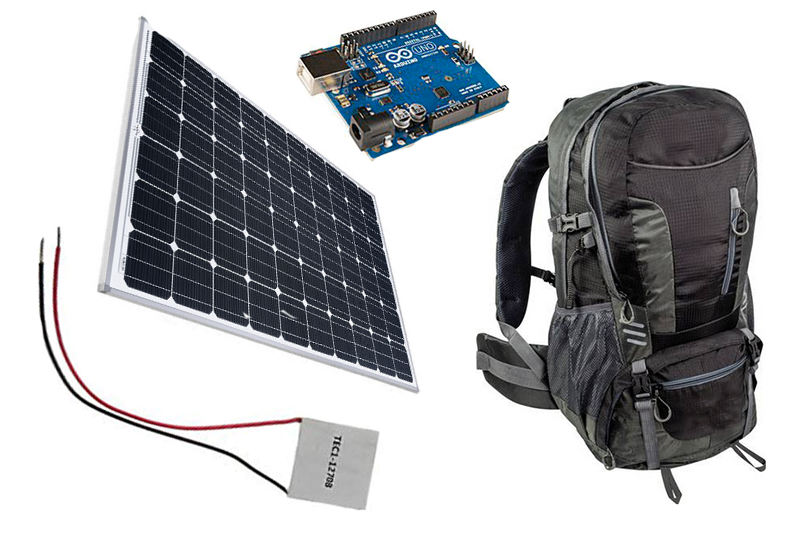

Deutsch Der Camping- bzw. Outdoormarkt wird von Jahr zu Jahr für immer mehr Leute interessanter, welche die Ruhe und Abgeschiedenheit suchen. Durch die steigende Anzahl an Outdoor-Begeisterten steigt aber leider auch die Belastung der Umwelt durch Verschmutzung. Eine Ursache ist das Verpackungsmaterial, das zum frischhalten von Speisen und Getränken benötigt wird und oft achtlos weggeworfen wird. Daher ist die Idee, das Verpackungsmaterial weitestgehend wegzulassen und erst gar nicht bei der Wanderung oder Camping mitzunehmen. Um das zu ermöglichen, schlagen wir die Entwicklung eines Wanderrucksackes vor, der Lebensmittel über Tage hinweg kühl und frisch hält. Kernelement ist dabei ein elektrisches Kühlsystem, dass effizient im Aufbau und in der Wirkungsweise ist und selbst Umweltschonend und autonom arbeitet.

English The camping and outdoor market becomes more and more interesting for more and more people every year, seeking peace and seclusion. Due to the increasing number of outdoor enthusiasts, unfortunately the burden of pollution on the environment. One cause is the packaging material that is used to keep food and drink is needed and often carelessly thrown away. Therefore, the idea of using packaging material as much as possible and not to take them with you when hiking or camping. In order to make this possible, we propose the following development of a hiking backpack that keeps food cool and fresh for days on end. The core element here is an electrical Cooling system that is efficient in construction and operation and works itself in an environmentally friendly and autonomous way.

Die Kühlung wird elektrisch mittels sog. Peltier-Elementen erreicht, die optimal mittels einer Regelung angesteuert werden. Der Regelungsalgorithmus ist dabei so gewählt, dass es zu einem möglichst günstigen Verhältnis kommt zwischen aktivem Kühlen und Aufladen der notwendigen Energiespeicher. Diese müssen aus Gewichts- und Platzgründen klein bleiben, was ein intelligentes Energiemanagement erfordert, welches sich adaptiv an die tatsächlichen Temperaturbedingungen anpasst. Das Aufladen erfolgt über Photovoltaik und natürlich, wenn möglich, über externe Stromquellen. Die Peltier-Elemente haben zwar im Gegensatz zu Kompressoren einen schlechteren Wirkungsgrad, jedoch keine beweglichen Teile, sind leichter und benötigen kein Kühlmittel, was als großer Vorteil im angesehen wird, wenn man zB. in geschützter Natur unterwegs ist. Um die Effizienz der Peltier-Elemente voll auszunutzen, und den Nachteil gegenüber Kompressoren dahingehend zu minimieren, ist ein zweiter wichtiger Punkt im Projekt, das Konzept zum Abführen der Wärme. Hier wird nicht auf die konventionelle Methode gesetzt mit einem Gebläse die Wärme abzuführen, was zu einem störenden Geräusch in der stillen Natur führen würde. Sondern die Wärmeenergie wird mittels Verdunstung abgeführt, was wesentlich effizienter und kompakter technisch umgesetzt werden kann. Die Wirkung des aktiven Teils wird somit von der Isolation nur mehr soweit unterstützt, wie es notwendig ist, und kann daher in der Entwicklung optimiert werden. Wobei auf kostengünstige und für die Outdoor-Aktivitäten geeignete Materialien zurückgriffen werden kann.

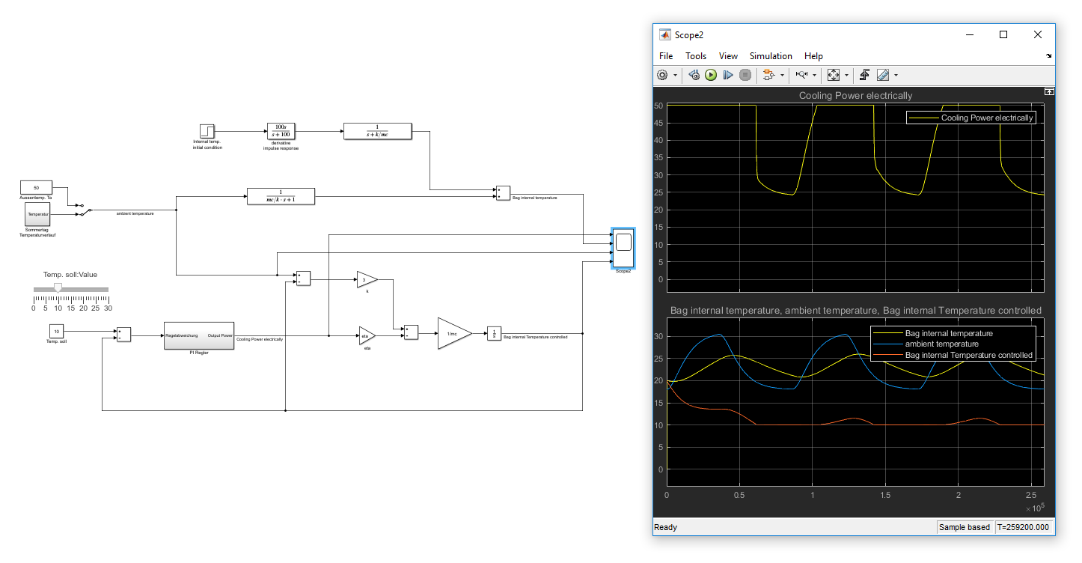

The control model should give a better insight into how the temperatures behave in the system. To achieve an optimal realistic result, a beautiful summer day is simulated. Due to the alternating outside temperature, the internal temperature of the backpack also changes, also included in the simulated. Days with a constant temperature are assumed. For this the pulse generator is suitable, since the heat energy emitted by the sun to the earth does not begin at the maximum and suddenly stop, two filters in series which distort this pulse in such a way that a realistic signal arises, which resembles a summer day. In case of a permanently constant temperature in the outside world and inside the system, a switch is used in the simulation to switch over to a constant temperature instead of a periodically alternating temperature. To be able to simulate the temperature in the interior, the properties of the backpack must be considered. To describe these better, in one of the next chapters a calculation example for the insulation has been made. There you can also find the formula used in the simulation. Basically, the simulated interior temperature is generated classically by means of Pt1 elements with consideration of the heat loss by the insulation of the backpack. To control the energy supply, a controller was built into the simulation. The temperature setpoint must be set upstream of the controller. At the end of the controller a saturation module is installed, which limits the maximum power to 50W. Now you can see a graph here the target temperature has been set to 10 °C (yellow line) The blue line shows the temperature in the backpack. It is especially nice to see that our system takes some time to fight the heat of the air sensed room. At this time a lot of energy is needed, on the later day the energy requirement drops down to half. To get the power at the thermoelectric modules a multiplier after the regulator is used to get the thermal power at the element by converting the efficiency. This is summed up with the remaining power in the system and outputs the final total power in the system, then a gain is used to incorporate the physical properties of the backpack. Finally, with the feedback you get the controlled temperature in the backpack. Here you can see the whole rule model again. The upper yellow graph shows the cooling capacity. The blue graph in the lower part simulates the outside temperature. The yellow graph in the second graph lets us see the changing temperature behaviour in the backpack without cooling, finally we see the temperature in the backpack using our cooling system.

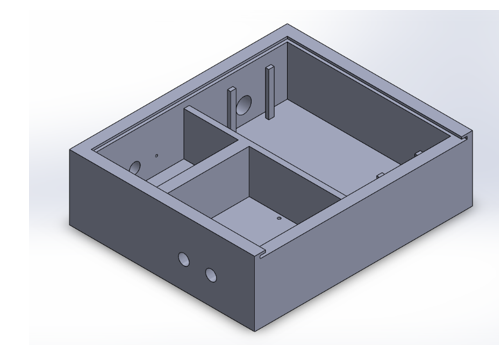

To integrate a protection device for our electronic components we were using our knowledge in a CAD program, we were able to design a construction that would protect our sensitive components from vibration and other environmental influences. The decision was made to create a box. Due to limited resources, this box had to be as inexpensive as possible but still stable enough. In order to achieve this, a design had to be created using the SolidWorks CAD program, which was then realized using an optimal manufacturing process. This manufacturing process was done by using an 3D printer. This system was chosen because of its availability and high material quality.

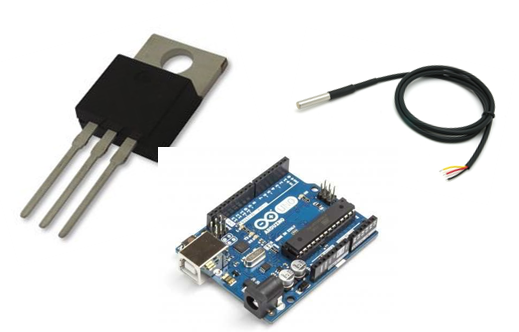

Most students of the HTL Mössingerstraße had to buy a microcontroller either in the third or fourth year due to teaching purposes. In our case this was the Arduino Uno Model R3. This microcontroller offers us the possibility to receive data. Since it is no longer used in the fifth year, this microcontroller is mostly unused in the possession of the HTL students. This offers us a cost-effective method to measure the temperature via sensors and process it. Some sensors will be considered these are to be found in the chapter Basics and Methods. The sensor we like most will eventually be used. Since the Arduino Uno R3 is used by us and is currently unused in our possession, it will of course also be described and compared in more detail in Basics and Methods with Andean Microcontrollers.After the sensor that seems to be the most advantageous has been selected, the program code has to be written. This is written in the program Arduino IDE. The advantages and functions of this program can be found in the section Basics and Methods. The finished program code should finally fulfill its function which is the output and processing of the data provided by the sensors.