Anna Marie Strucl

image processing

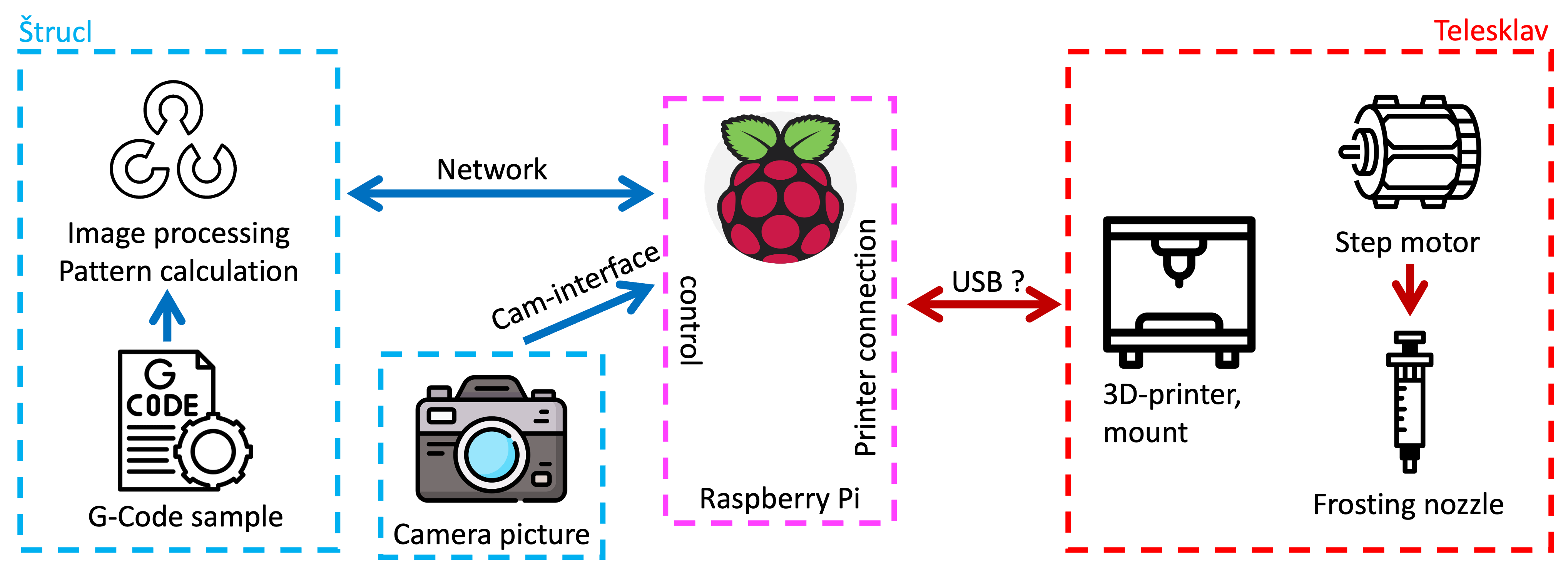

English Until now, cookies are still ornated by hand. Which requires a lot of people and high expenditure. The procedure here is that the production takes many steps with the individual frosting topics. The goal of our project is to eliminate that work and make it automated. A camera detects the cookie on the pad of the 3D-printer, determines the size and the alignment. In the background is a database with pre-assembled designs for each cookie variety. The selected pattern will be applied through a nozzle. For the triggering and image processing, a microcomputer is used.

German Derzeit werden Kekse, wie zum Beispiel Lebkuchenherzen, noch manuell verziert, was mit einem hohen Personal- und Kostenaufwand verbunden ist. Dabei verzieren mehrere Personen die Kekse Schritt für Schritt mit verschiedenen Zuckergussarten am Fließband.

Das Ziel dieses Projekts ist es, den Prozess der Keksverzierung zu automatisieren. Eine Kamera erfasst den Keks, der auf dem 3D-Druckerpad liegt, und bestimmt dessen Form sowie Ausrichtung. Anschließend wird aus einer Datenbank vorgefertigter Muster das passende Design ausgewählt und mithilfe der Zuckergussspritze auf den Keks aufgetragen. Zur Steuerung und Bildverarbeitung kommt ein Mikrocomputer zum Einsatz.

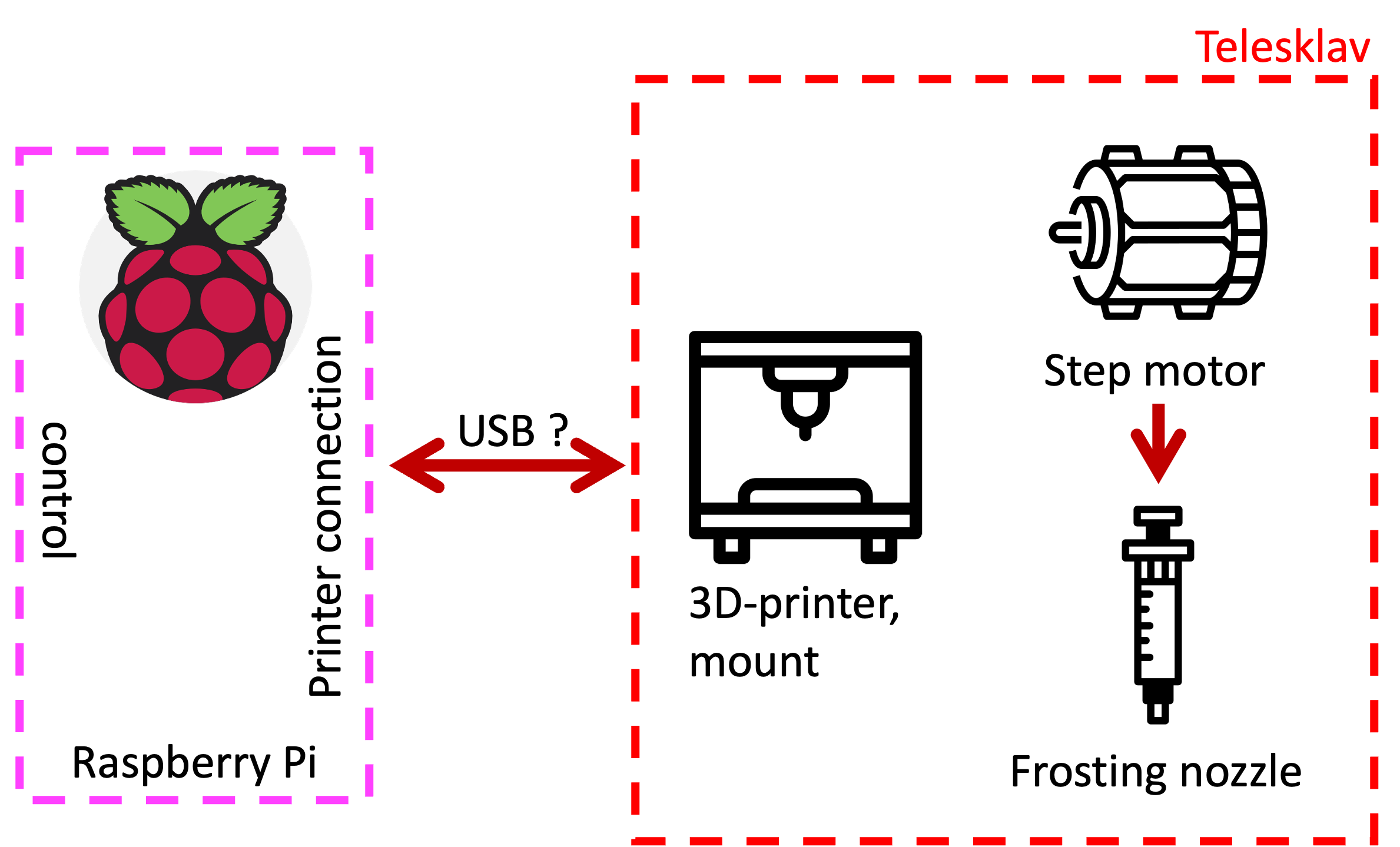

The Raspberry Pi controls the rotation for the cookie. An installed camera on the bar of the 3D printer determines the shape and place of the cookies. Therefore, the coordination of biscuits is forwarded to the Raspberry Pi. The microcontroller then controls the movements of the nozzle and ornates the cookie.

The frosting is stored in the nozzle and pushed down through a threaded spindle, connected to the forcerer. To obtain the liquid precisely, a step motor is employed. When the nozzle depletes its frosting supply, the user can either replace it with a fully loaded one or refill the existing nozzle.

A camera captures an image of the printer pad, where a variety of cookies are displayed. The image is subsequently rectified using corner detection. Subsequently, contour detection is employed to discern the shape of each cookie, which is subsequently displayed.

Utilizing the extracted contour, a G-code file is generated for the printer. This G-code is then transmitted to the printer via OctoPrint on the Raspberry Pi, enabling its execution.