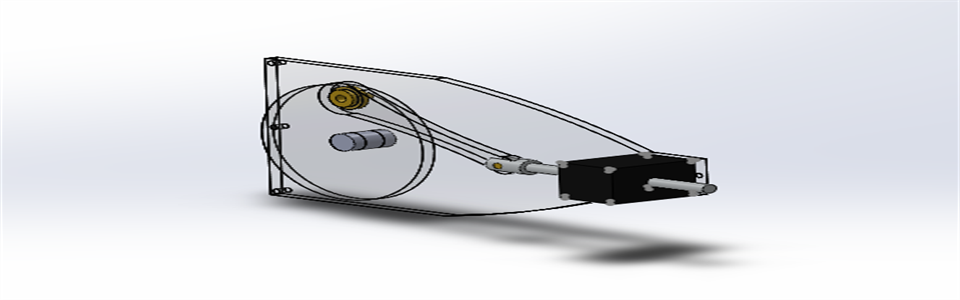

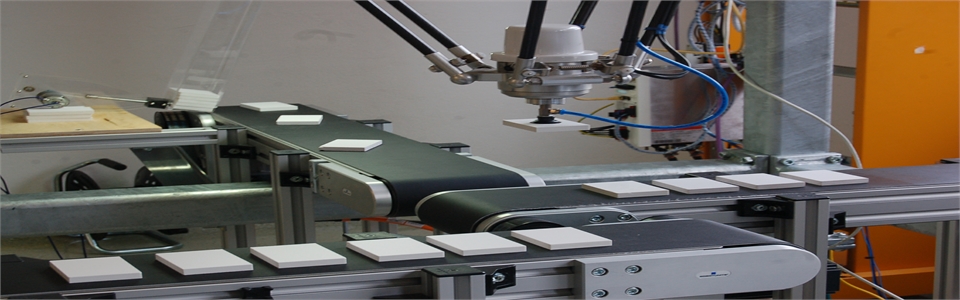

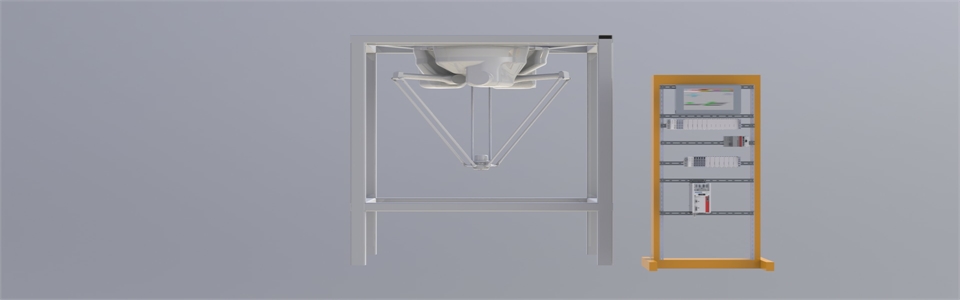

THE PROJECTOur project focuses on the construction of a sorting machine. We work with a Yaskawa Motoman MPP3 -Delta Robot. This robot is mainly used in the industry for picking, packing and palletizing functions. Our idea was to construct a eject machine that puts our work pieces on the first conveyor belt. After that the work pieces run in the camera system of our camera detection system and evaluates the position, colour and size of our work pieces. After that the system calculates the whole data with MotoPick and sends the data back to the robot system. Then the robot is able to pick up the pieces and place it on a programmed place (e.g. on one of our two conveyor belts). These steps are going to be so fast that a human person isn’t able to see what the robot is doing, for that we are going to make a video of the system in super-slow-motion at the end of our project. The robot uses a Vacuum to place our work pieces on the conveyor belts.

Here is a short preview how it can be realized...

Source: http://www.youtube.com/watch?v=5tfiWpx-cS0

Main parts of our project:

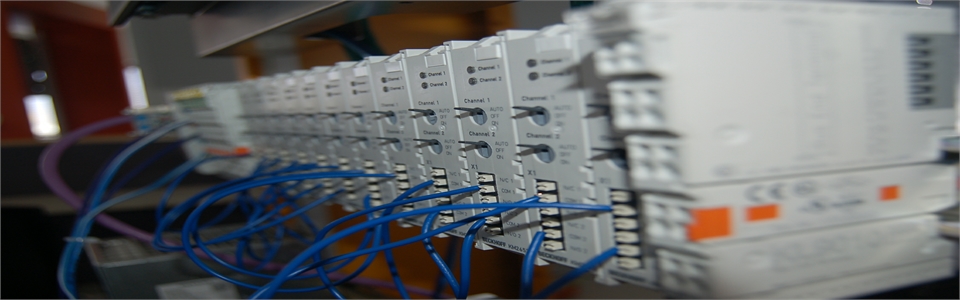

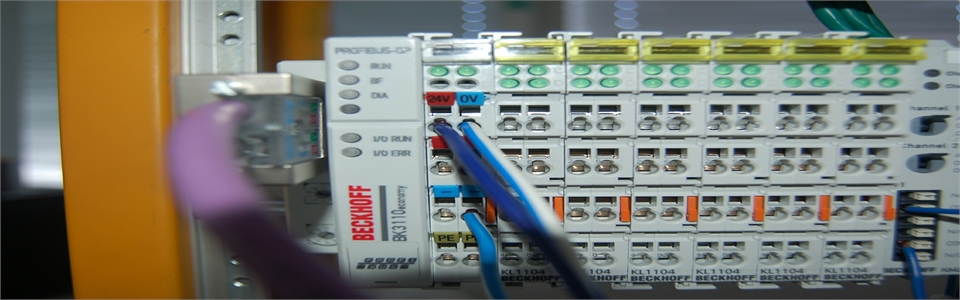

Construct a "Eject Machine" Configure all of our PLC components with TwinCat Install the Control Panel Make a conveyor belt control software Make a Visualization for our conveyor belts Install the robot Comissioning of the whole system Programm our main Programm System safty check Film our project in super-slow-motion |

|

|

|---|---|---|