Details

On this page you will find a closer description to our project.

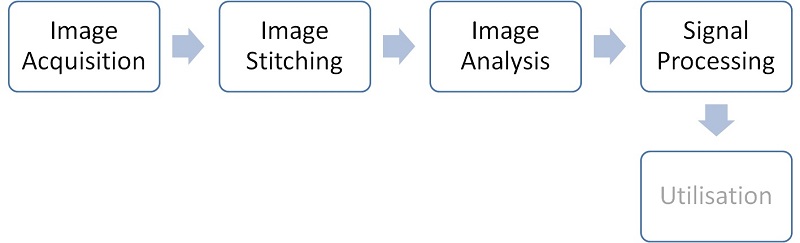

After a long time of research for the right sensor we agreed upon solving the main target of bottle identification with a camera based system for several reasons. The following picture describes the system architecture and the four functional aspects within the project.