On this website we will show you some of our plans and concepts in greater detail.

Controlling concept

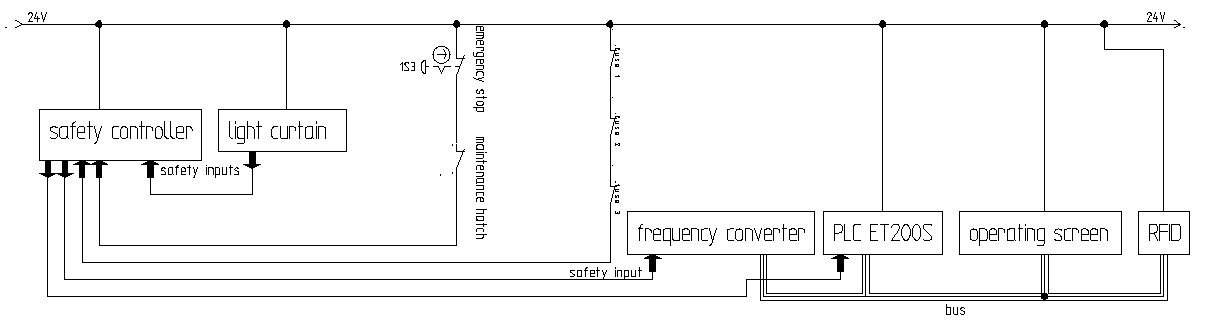

Here you can see one of our early controlling concepts.

On the left side the safety part of the control system can be seen. It will be explained more in detail in the safety technology tab.

On the right side you can see the controlling part.

On the left side the safety part of the control system can be seen. It will be explained more in detail in the safety technology tab.

On the right side you can see the controlling part.

PLC

The brain of our system is the ET200S which does the whole controlling part. The ET200S is a PLC which has a S7-315 CPU built in but costs far less. We have decided to use this PLC because we can use the real time Profinet bussystem to control the frequency converter with it.

Frequency Converter

As a frequency converter we have decided to use the Sinamics S110. This frequency converter is one of the more expensive ones but it complies with all the safety regulations we have to observe.

Safety requirements:

STO: Safe Torque Off: Safety input that puts the frequency converter on halt on demand.

SBC: Safe Brake Control: Evaluates the status of the brakes and also recognises a broken cable.

Safety requirements:

STO: Safe Torque Off: Safety input that puts the frequency converter on halt on demand.

SBC: Safe Brake Control: Evaluates the status of the brakes and also recognises a broken cable.

RFID System

We have also decided to replace the old mechanical counter by an RFID system with appropriate tags. This has the advantage that we always have the an absolute position recognition without any more mechanical effort. These tags are mobile EEPROM memory modules, which save the actual shelf number.