Safety Technology

The safety system of the rotomats is obsolete and moreover partially bridged. Because of this the potential dangers that occur while operating the rotomats are very high.

That is why we developed a whole new safety system of the latest technology in cooperation with the company Schneider Electric. Here you will find an overview of the new componments.

Light Curtain

To protect fingers and hands from possible dangers while operating the rotomat a light curtain named XUS LBQ is installed at this system.

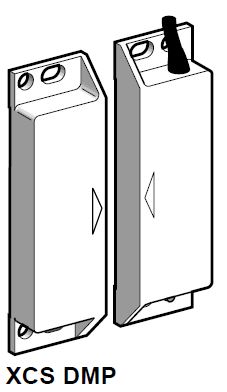

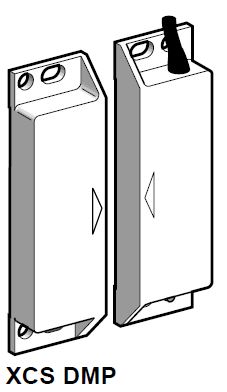

Magnetically Coded Switches

Under the rotomat there is a maintenance hatch. With this maintenance hatch the user has access to the motors and the gearboxes. If this maintenance hatch is being opened, a sensor must recognise this and the rotomat must not be able to be operated because there is a big risk of injuries otherwise. We have decided to use a magnetically code swith to fulfill this task. Magnetically coded switches give us a higher clearence than mechanical sensors and are more reliable. Only if both the plates of the switch lie above each other the interal contacts will be opened.

Safetycontroller

To evaluate the safety sensors a safety controller of the type XPS AFL is used. It evaluates the state of the safety sensors and the emergency stop button with the help of the safety inputs. Only if all the sensors enable the operating and the emergency stop button was not pressed the frequency converter will be enabled via safety inputs.